AeroBarrier is a cutting-edge envelope sealing system

that simultaneously measures and seals building envelope

air leaks.

Step 01

Prep and Setup

Step 02

Pressurize and Apply

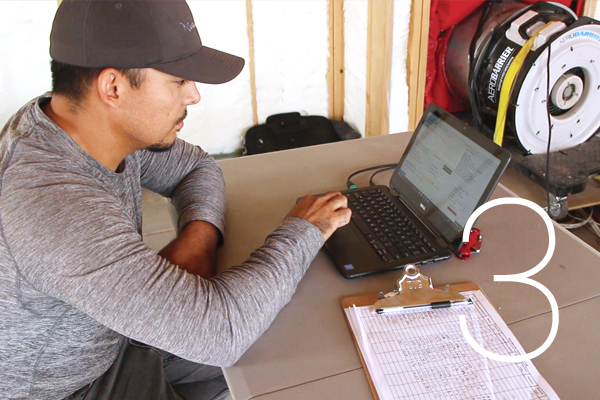

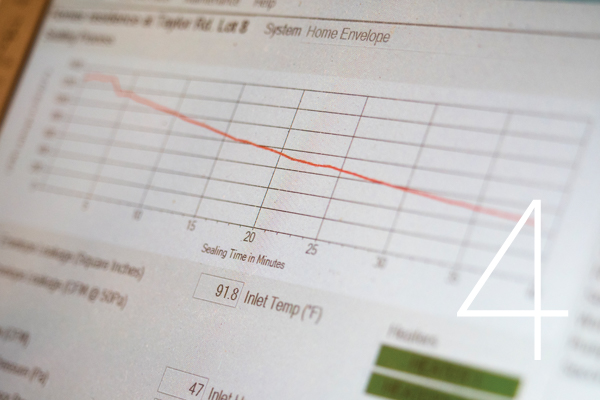

Step 03

Real-time Results

Step 04

Clean Up

Watch our AeroBarrier Process and Timelapse Videos

Request a Free Quote Now

AeroBarrier easily integrates into any build process and removes the need for hiring additional labor to meet the new air sealing demands.